The first step towards digitising your shopfloor has never been so easy!

The first expert discussion is all about you.

If you pick or assemble a large number of small parts in your production...

... Then you are probably familiar with the following situation:

- Mispicked / incorrectly removed items

- The wrong quantity was removed

- No easy access to stock data

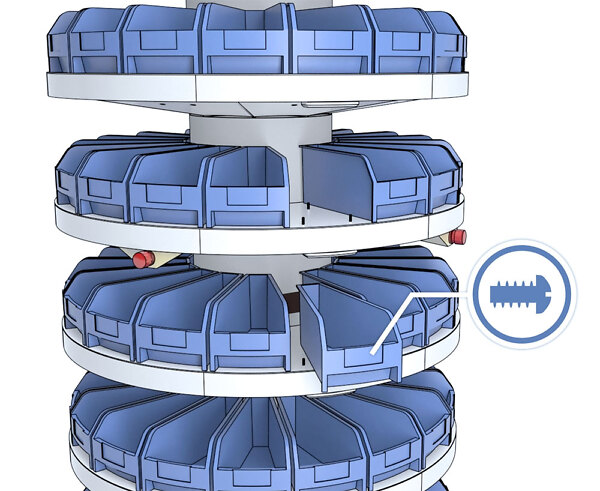

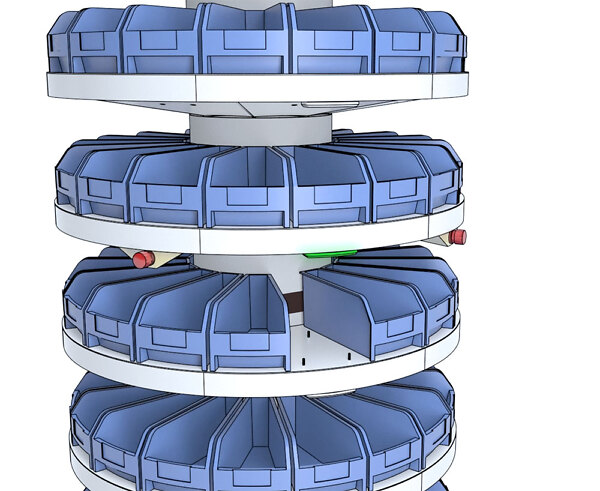

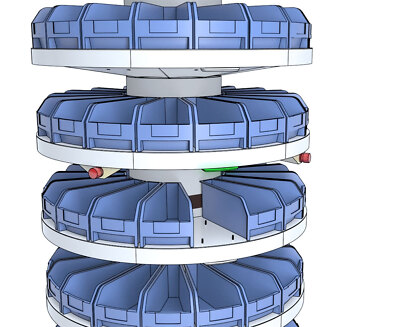

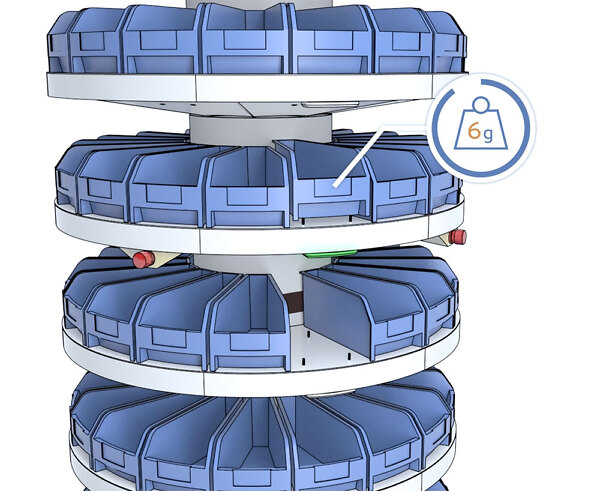

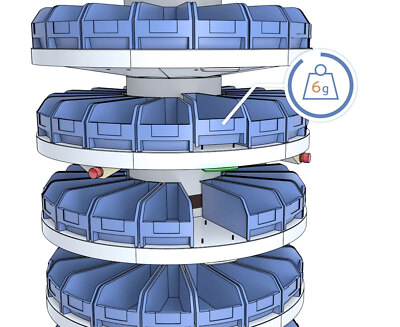

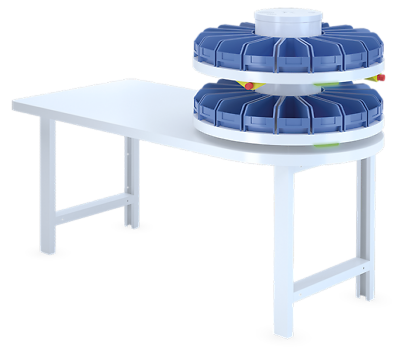

This results in increased effort in stocktaking, a lack of clarity and high error rates in the process. This is where our C-parts management solution comes in - the SETAGO® Storage Tower and the SETAGO® Assembly Station.